Description

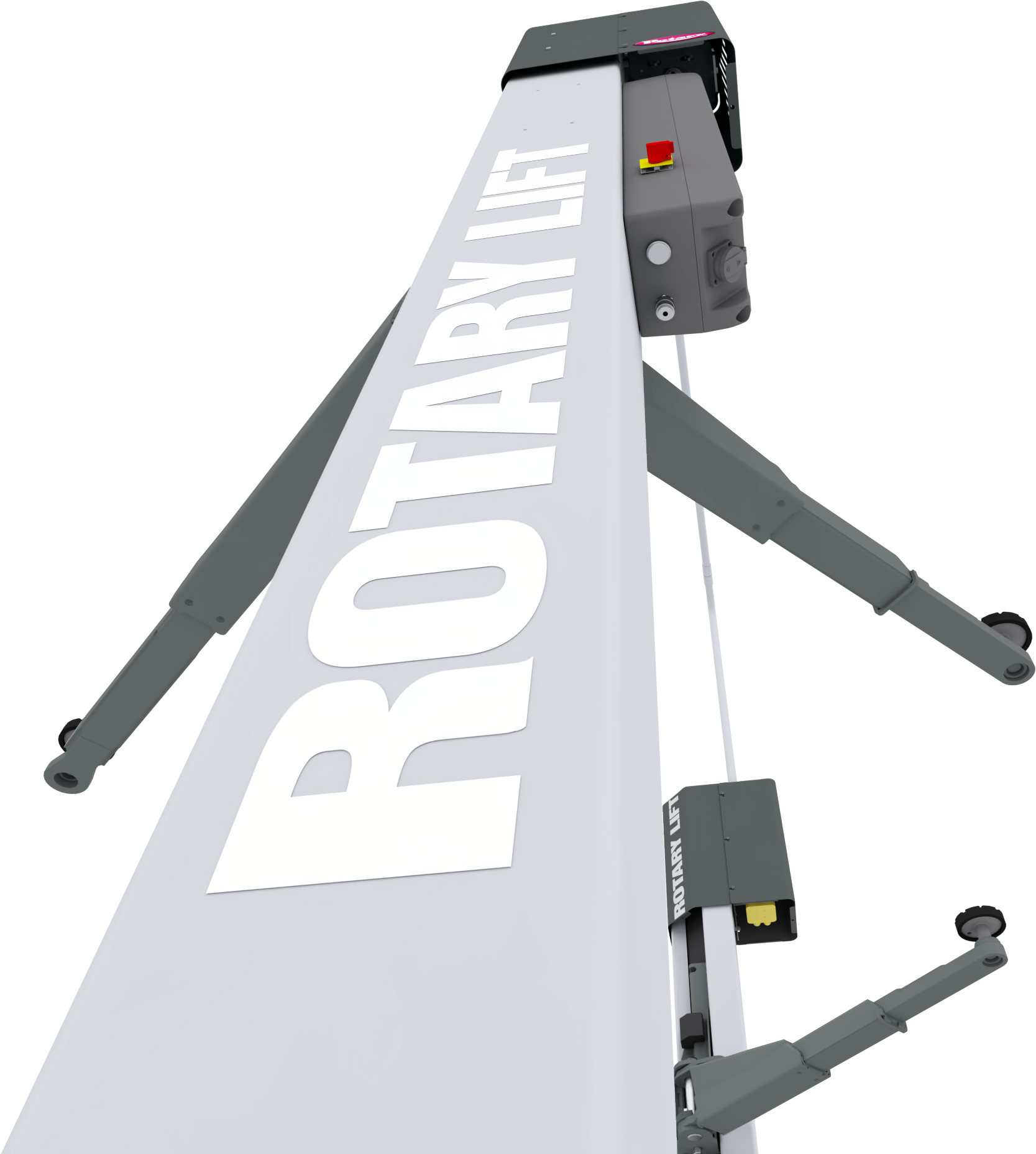

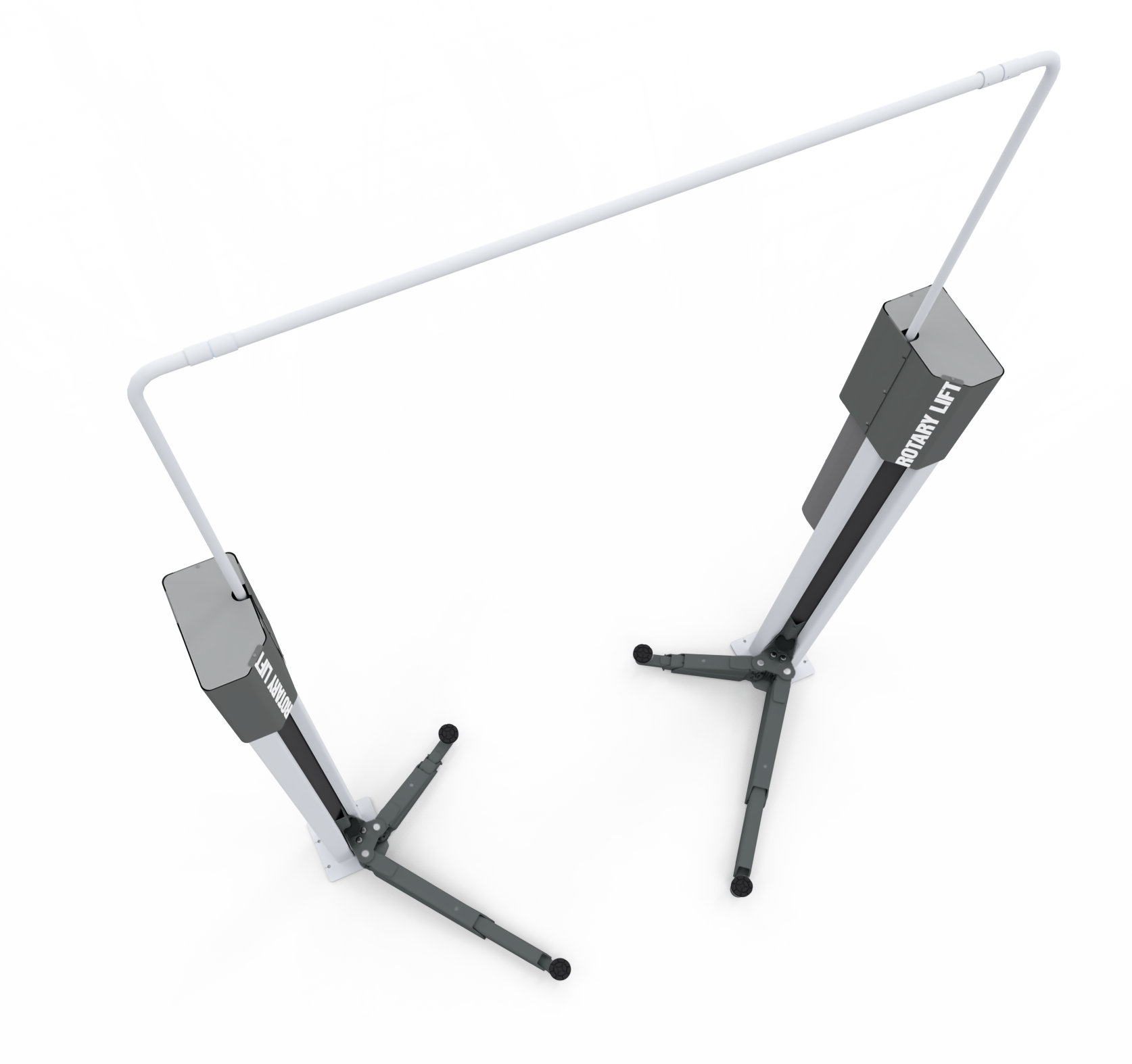

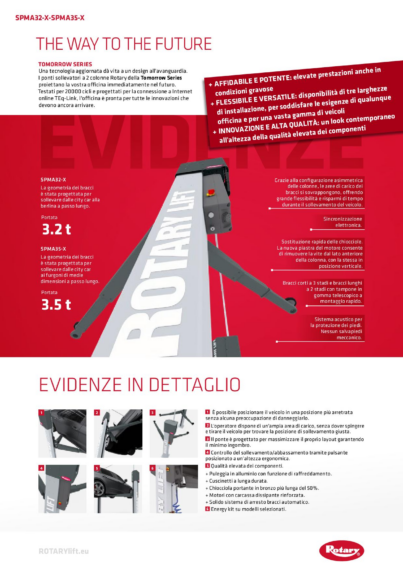

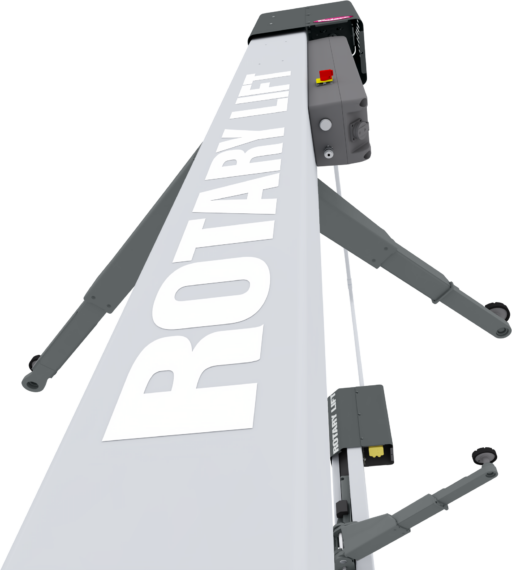

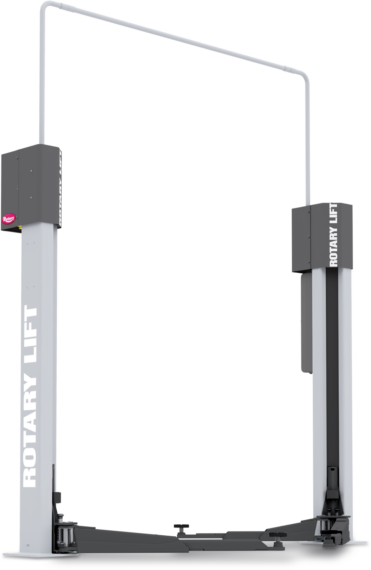

Tomorrow Series – The way to the Future

- Reliable and powerful: solid performance even under demanding conditions

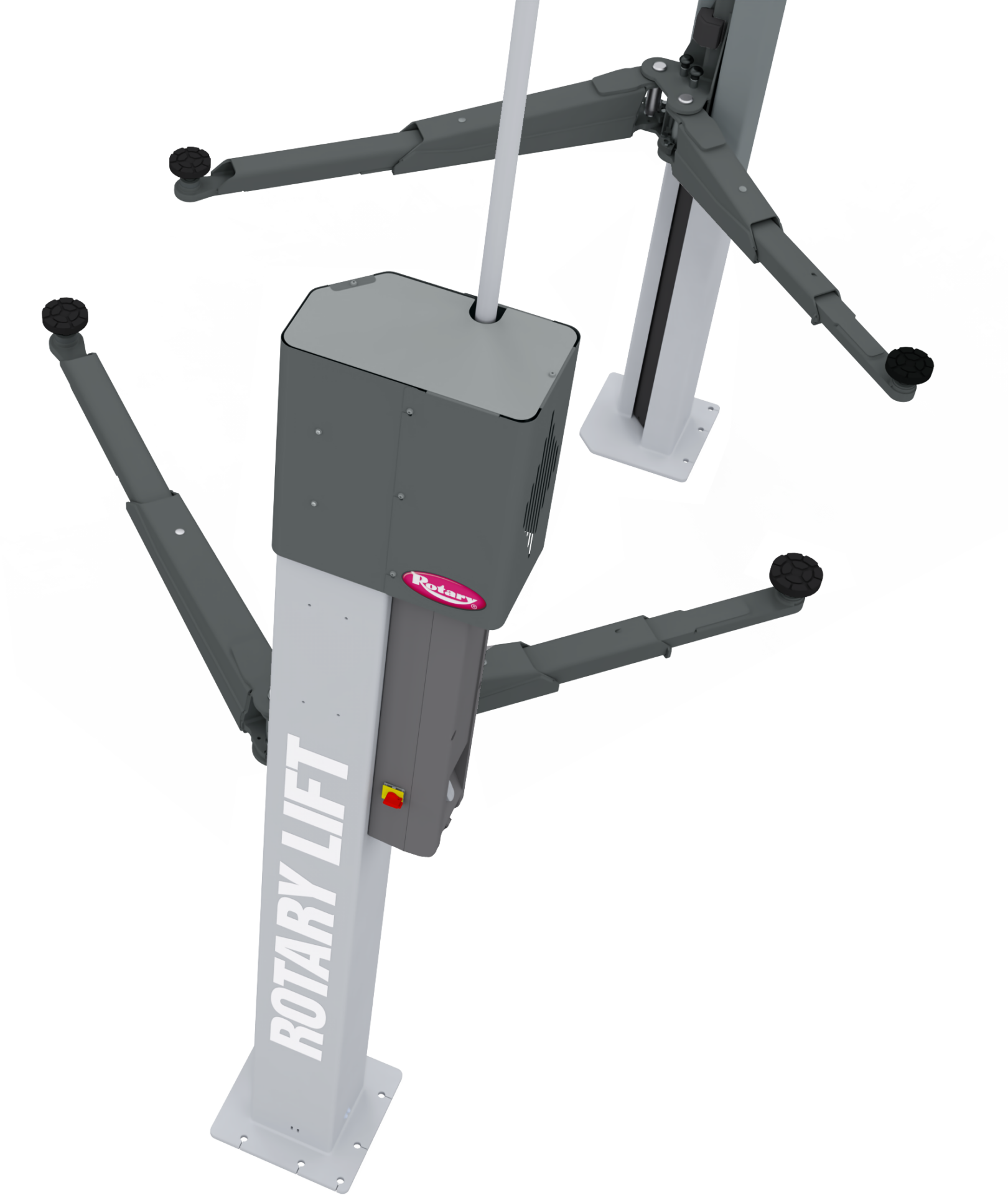

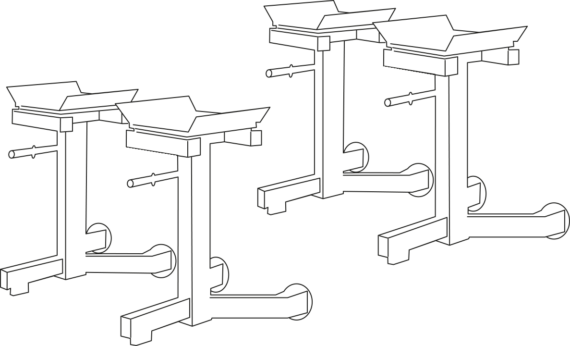

- Flexible and versatile: three possible installation widths to satisfy any workshop needs and applicable to a wide range of different vehicles

- Modern and premium: a contemporary look meets the premium quality of components

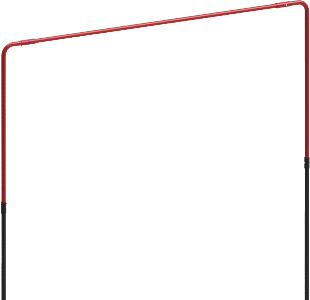

Revised technology shaping a modern design. The 2-post lifts of the Tomorrow Series of Rotary raise your workshop immediately into the future. Tested for 20000 cycles and designed for TEq-Link online internet connection, your workshop is prepared for all innovations that are yet to come.

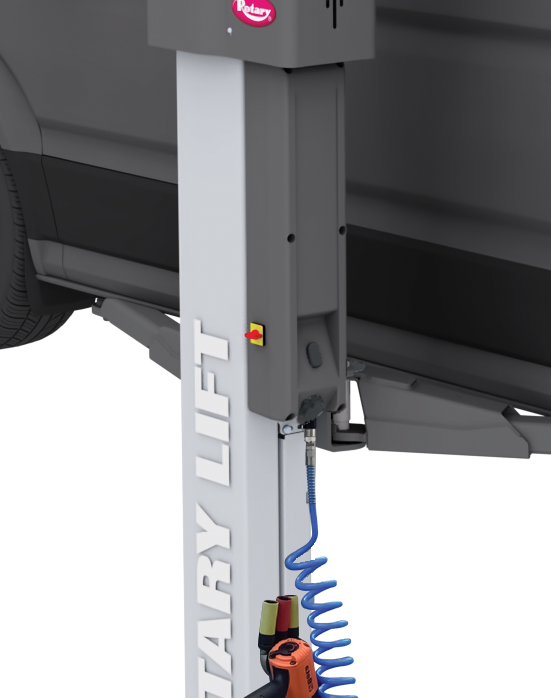

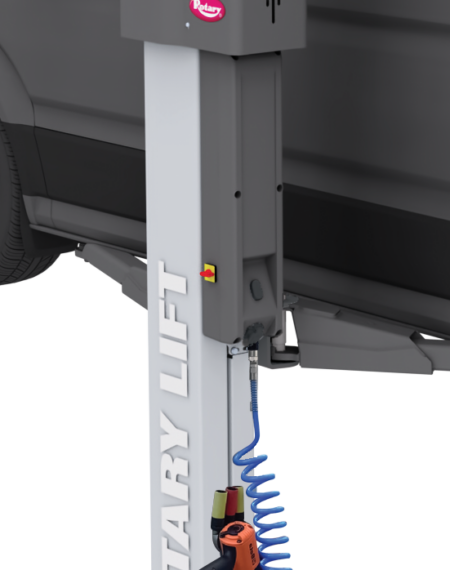

- Minimum routine maintenance: The operating parts require little time for easy replacement or maintenance reducing the risk of error on safety elements.

- Guaranteed safety and quality over the time: The lift is equipped with premium components that guarantee durability and maximum safety for the operator.

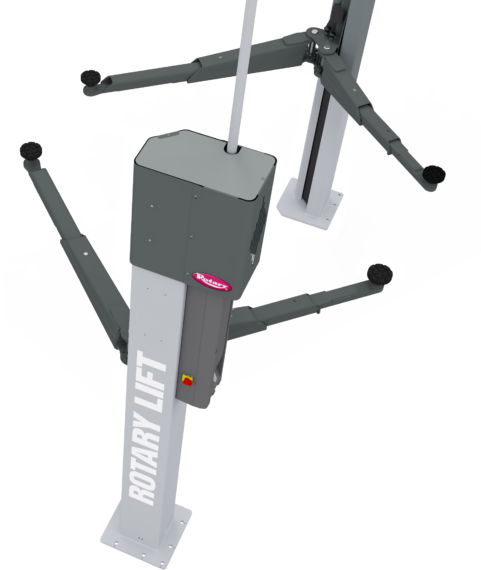

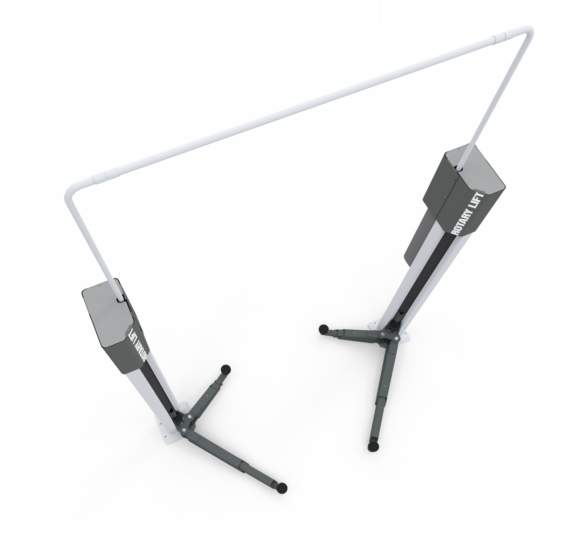

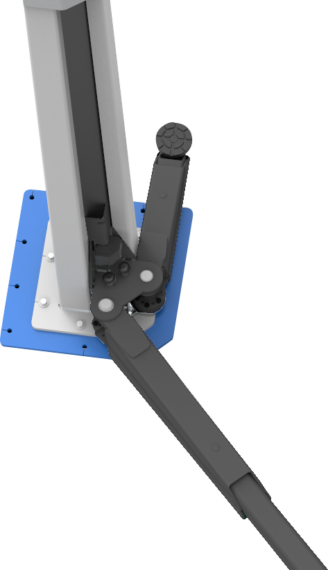

- Smart and flexible installation: Up to 20% improvement in installation time. The electronic synchronization avoids the installation and adjustment of the realignment cable. The lifts can be installed in a flexible way thanks to three width-adjustable positions.

- Quick and easy operations: The working bay is free of obstacles and the operations can be performed safely and comfortably.

- TEq-Link connected workshop

- Workflow management

- Data management and statistic

- Job booking

- Real time diagnostic

- Preventive maintenance

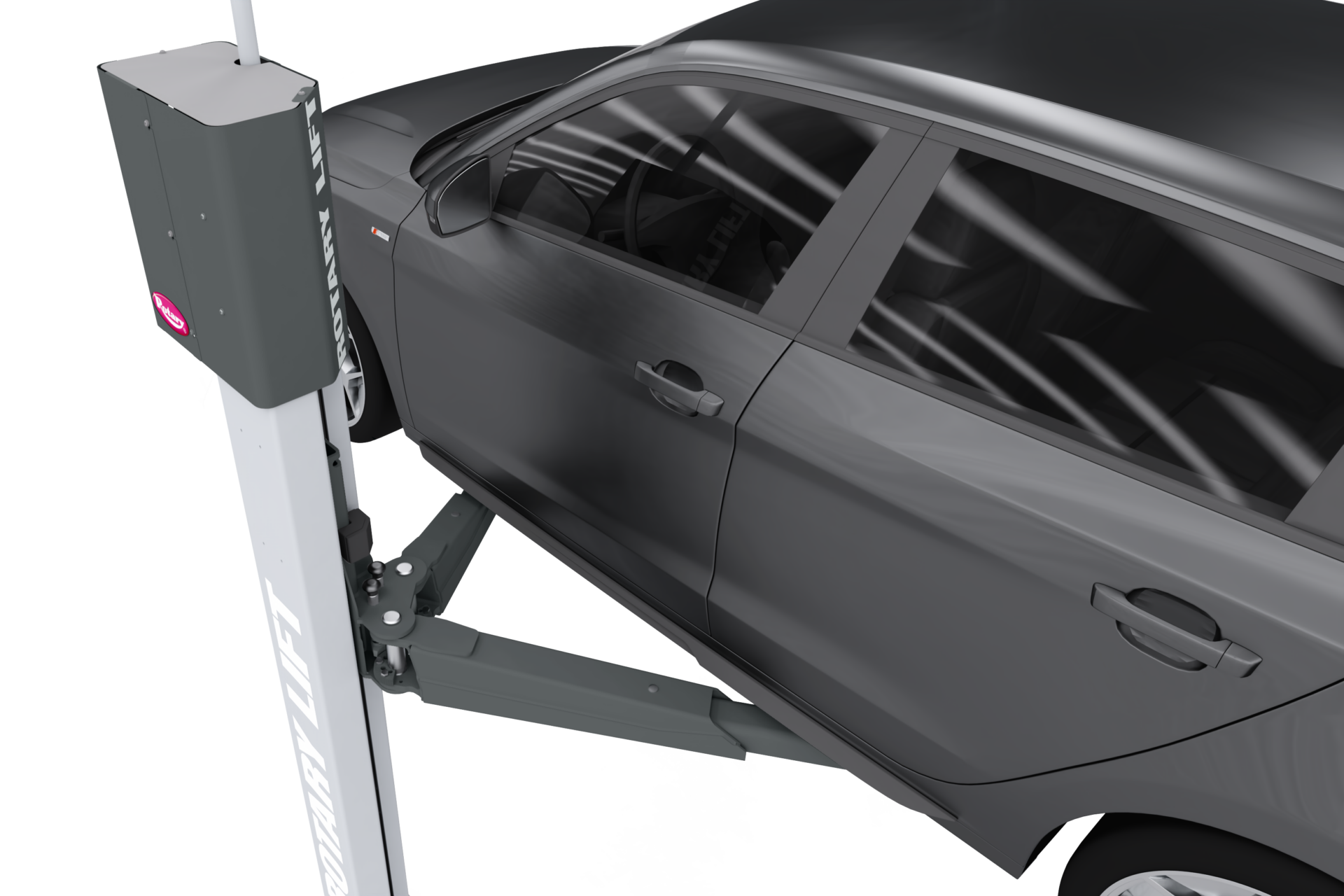

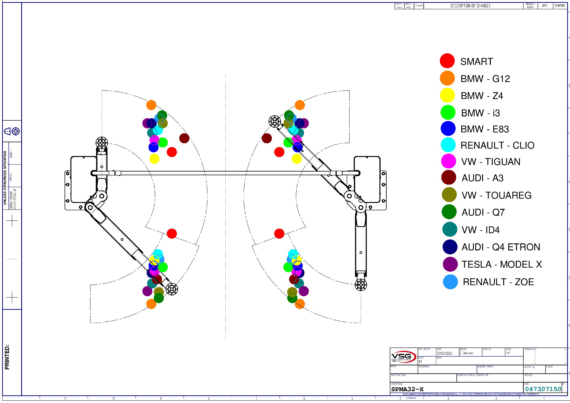

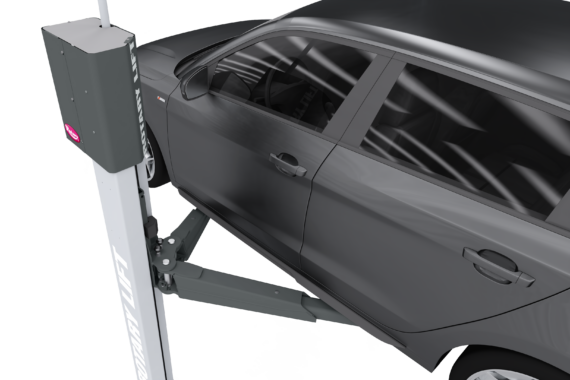

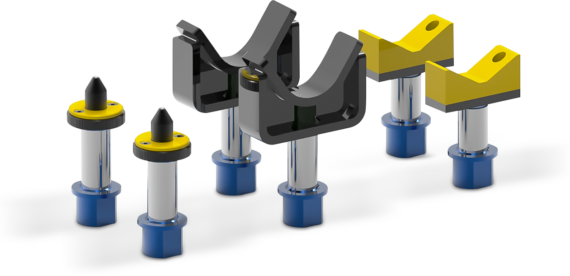

- The geometry of the arms was designed to lift anything from city to longwheelbase cars.

- The vehicle can be placed backward without any worries about damaging the vehicle itself.

- The operator has at his disposal a wide loading area, without the necessity of pushing and pulling the vehicle to find the right lifting position.

- The lift is designed to maximise its layout while ensuring minimum space requirements.

- Push bottons control (up/down) at an ergonomic height.

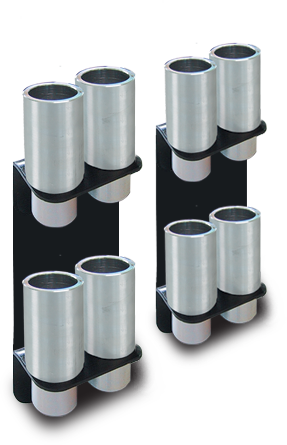

- Premium quality of components:

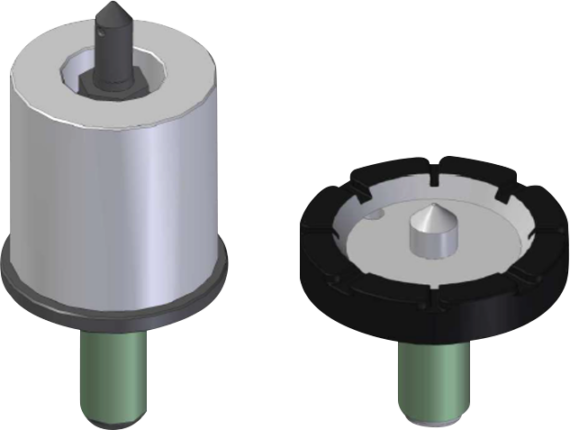

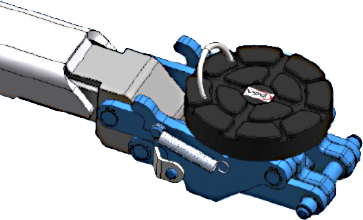

- Aluminum pulley with cooling function

- Long lasting bearings

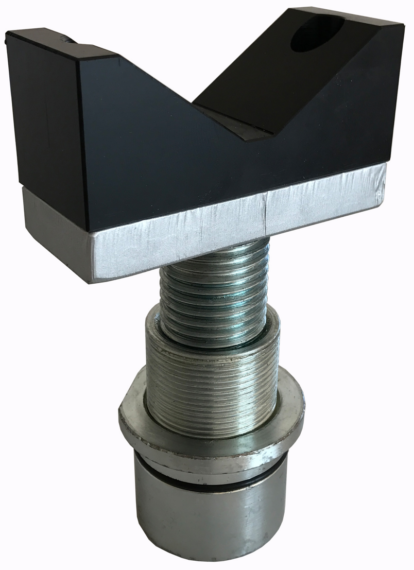

- 50% longer, bronze load nut

- Motors with reinforced and cooling casing

- Solid automatic arm locking

- Energy kit

- Thanks to the asymmetric design of the columns, the loading areas of the arms overlap, granting great flexibility and time saving when picking up the vehicle.

- Electronic synchronization

- Quick nut replacing: New motor plate that allows to remove the screw from the front side of the column with the column standing

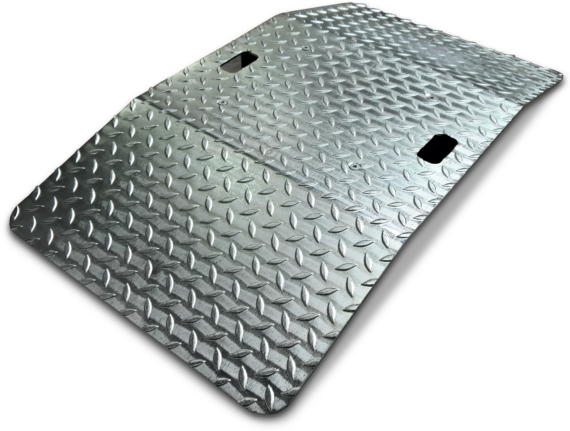

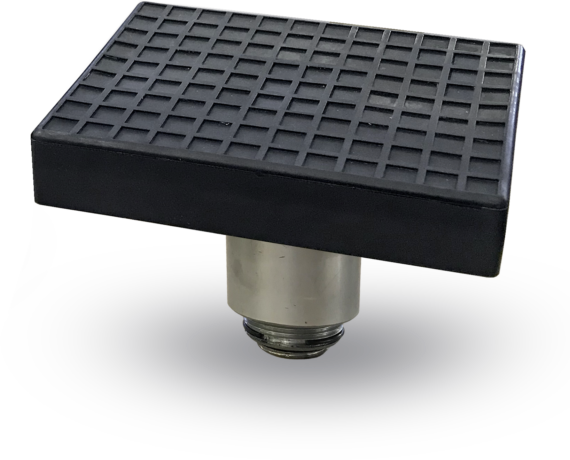

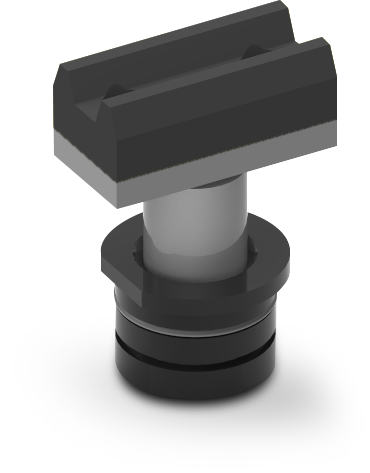

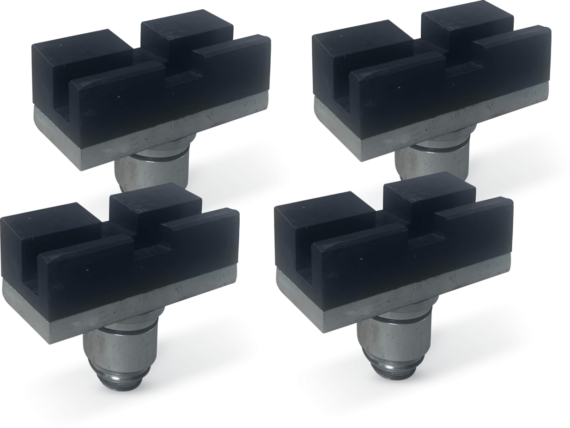

- Short 3-stage arms and long 2-stage arms with quick fit telescopic rubber pad

- Equipped with an acoustic anti toe trap system – Free from mechanical foot guards