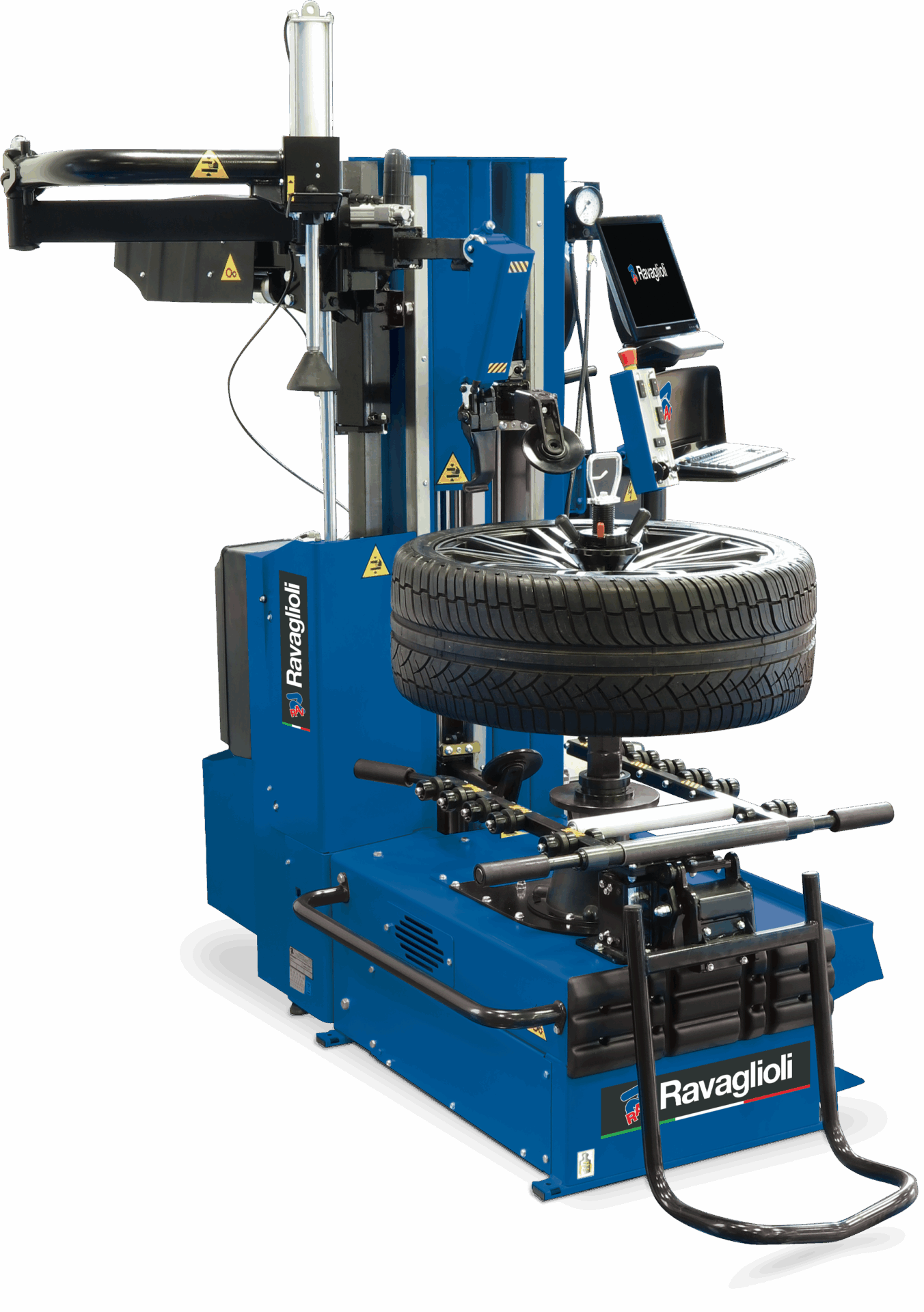

Описание

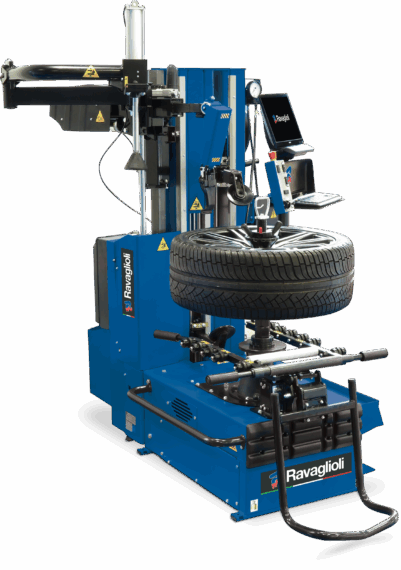

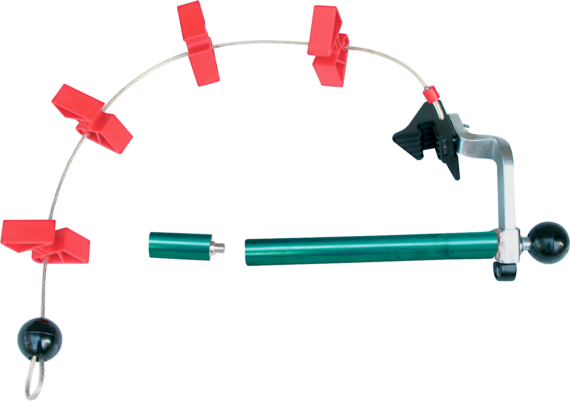

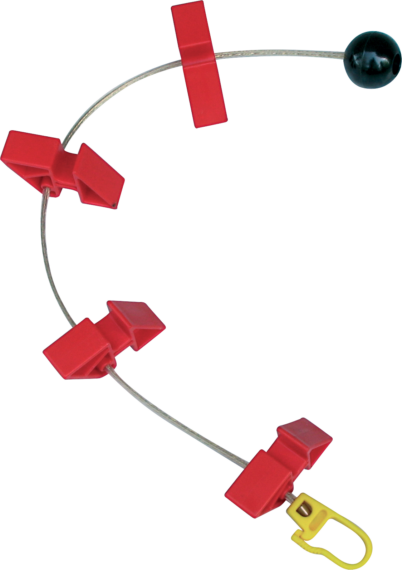

Version with patented TOP inflation device

- 3 Working modes

- Standard

- Automatic (like G1200)

- PC managed

- Automatic mode

- Place the upper roller on the rim edge.

- Rotate the wheel and place the valve in start position.

- Press start button and the tyre changer is ready to work in automatic mode (G1200 program).

- Once the first wheel is done, the start position will be reached fast and automatically to repeat the job again and again.

- Patented lever-free tool

- Pneumatically operated beadbreaker discs:

- Built in scratch-proof material for complete rim protection.

- The rim edge sensor allows the roller to move forward automatically, enabling it to work on the bead without damaging the tyre’s sidewall.

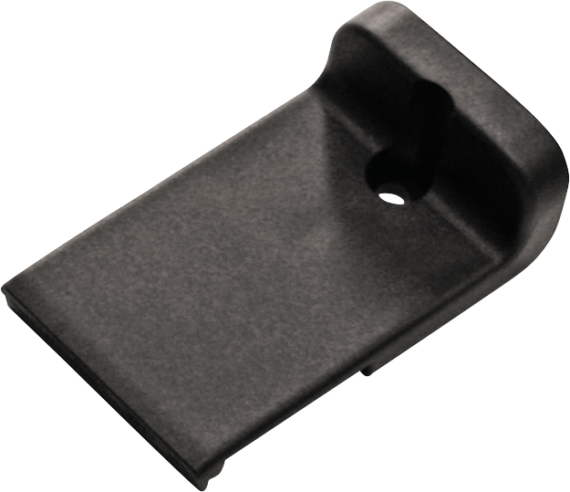

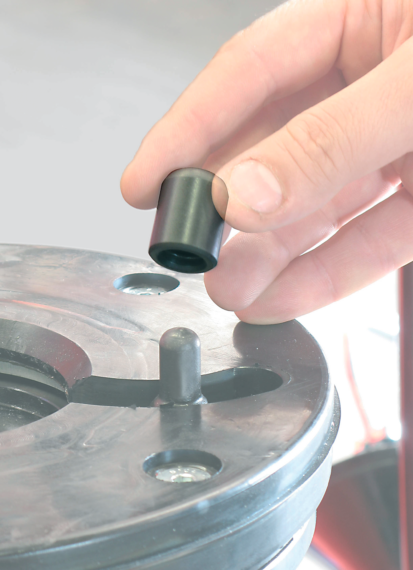

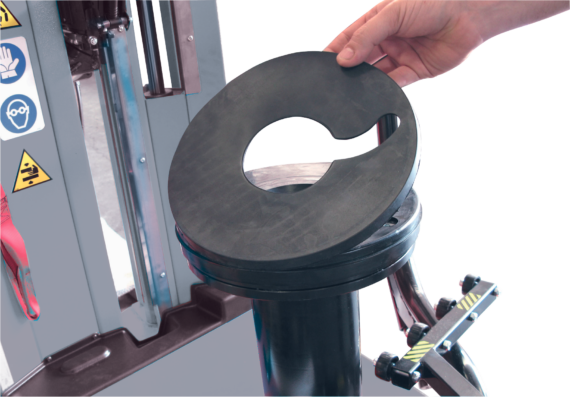

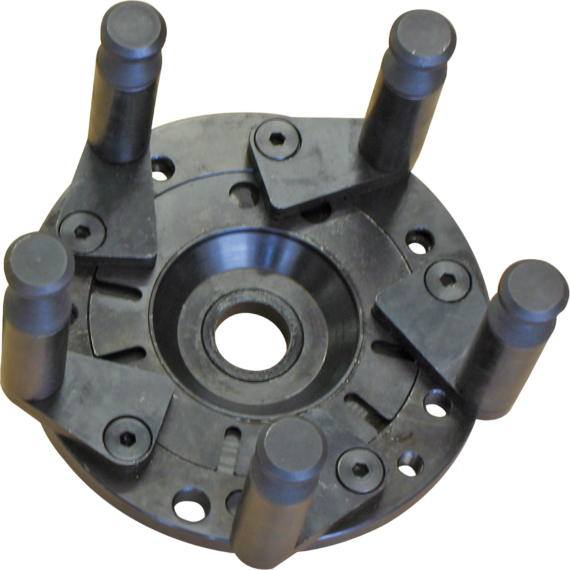

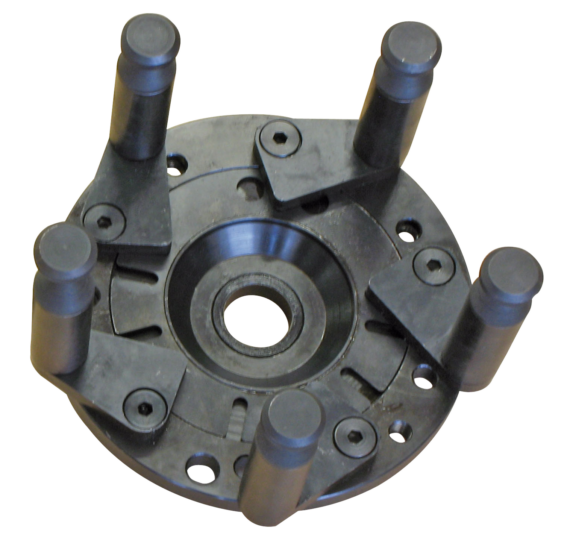

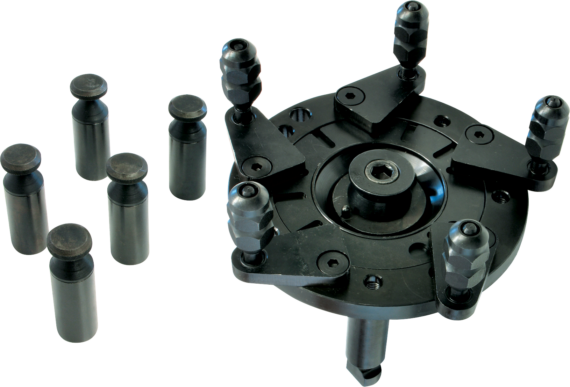

- The central rim locking system, suitable also for reverse rims, consists of a central pin with cone. The effort is minimal thanks to the special plate on which the wheel lays. The plate is floating, therefore offering a self-locking mechanism.

- 3 adjustable working heights

- Data bank: It is possible to memorize up to 100000 different wheels by:

- client name

- plate number

- any notes

- Data transfer: It is possible to transfer data among tyre changers — This is particularly useful when working with many tyre changers:

- at the same location (large tyre shop, vehicle or tyre manufacturing plant)

- at different locations (tyre shop chain, car dealer group)

- Customized data and a quick training allow easy demounting of difficult tyres even by inexperienced workers.

- PC managed operation

- Fill in the tyre data.

- The software automatically selects the best program among SOFT / STANDARD / RF/UHP — The user can decide to switch to another program (but the software does not allow programs which are not appropriate to that type of tyre).

- Place upper and lower rollers at the rim edge and the valve at start position.

- Press start button and the tyre changer will carry out the programmed job with minimum assistance.

- At any time a job can be stopped and then continued with no need to start again the entire cycle.

- Targeted job: The pre-set and dedicated cycle reduces working times

- When turned on, the tyre changer asks to choose the requested function:

- demounting/mounting tyres (standard operation)

- repeated demounting (as removing tyres from rims at car wreckers)

- repeated mounting (as in car manufacturing plants)

- User-friendly console:

- Simplifies the operator’s learning process

- With buttons for operating the rollers and tools

- Super fast:

- Once a wheel is clamped on the plate, demounting and mounting (complete cycle) varies from 55” to 75” including run-flat and UHP.

- Since 35” is the total time required to lift, lock, unlock and unload the wheel, the total time required for a complete cycle is as low as 90 — 110 sec from floor to floor position.

- Invemotor: Speed set by the operator, exactly as required — Inverter with governor to protect the tyre.