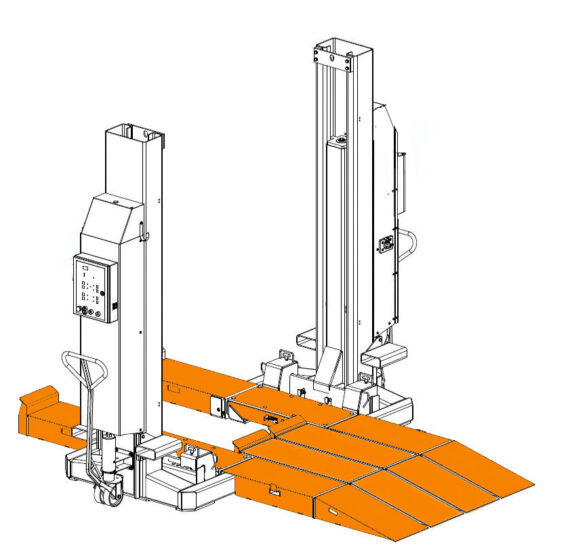

Description

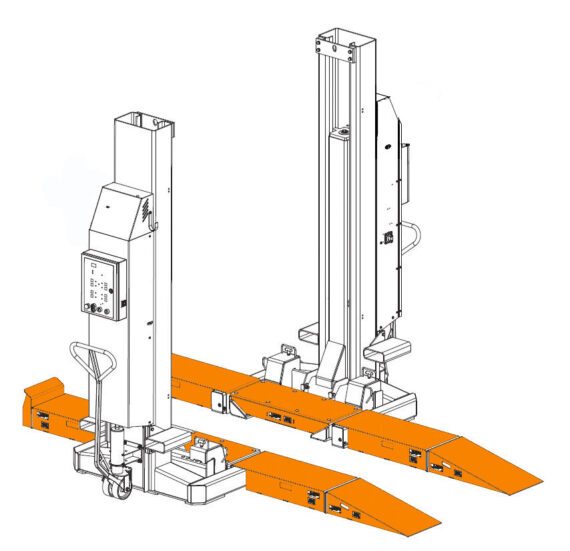

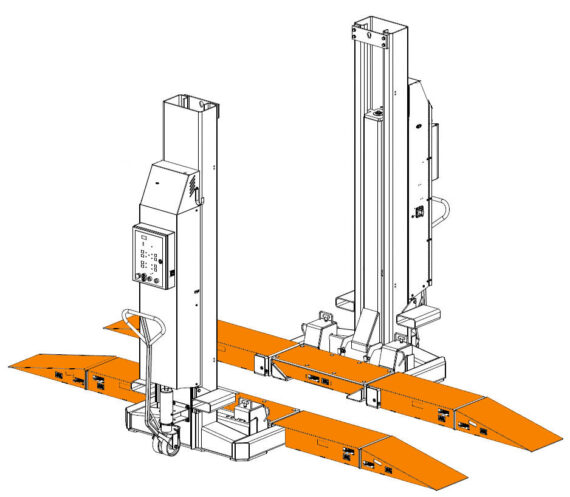

The mobile wheel gripper systems by Blitz are a perfect synthesis of flexibility and stability. Free Areas – make optimal use, both in the workshop as well as outdoors.

- Double overload protection ensures security

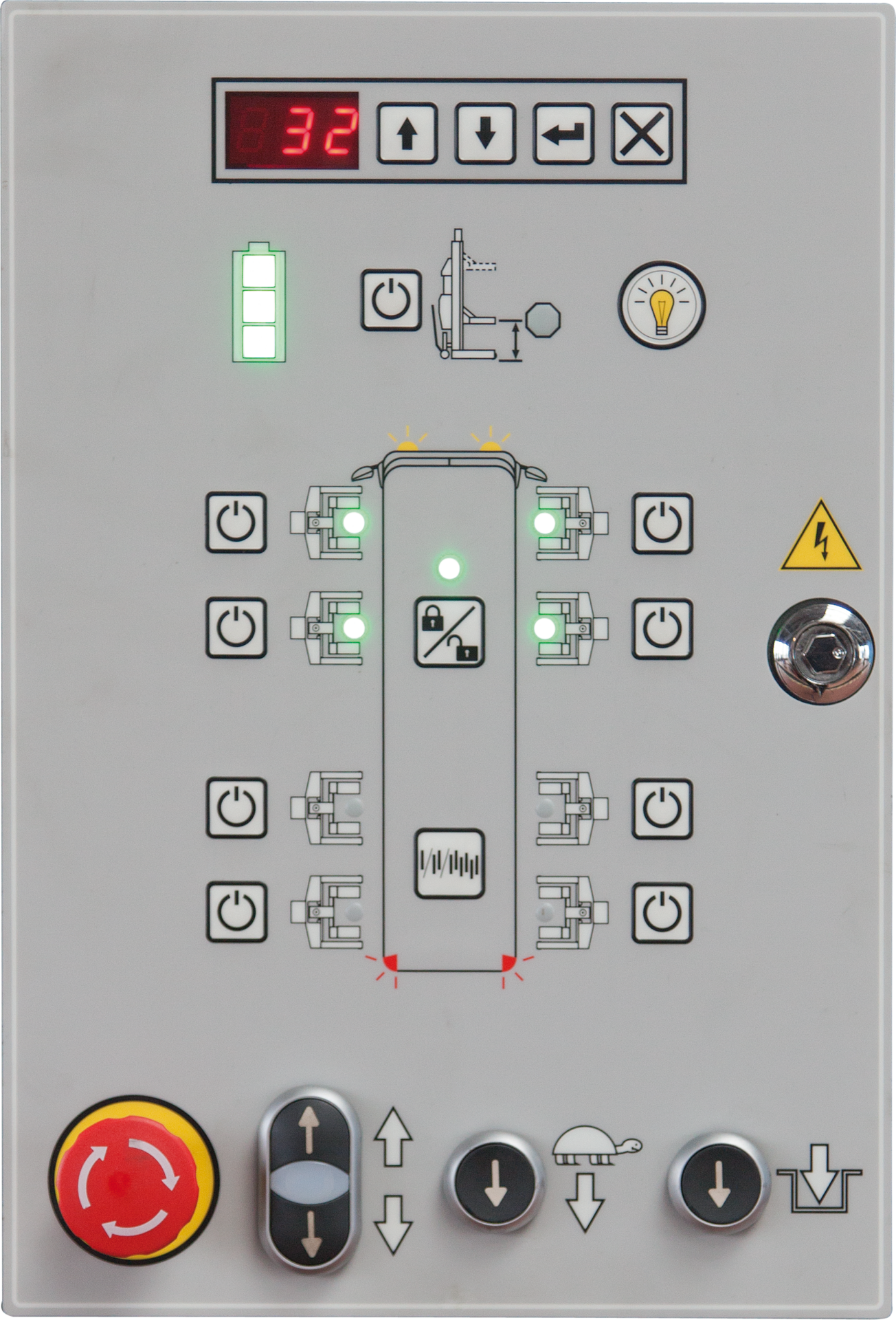

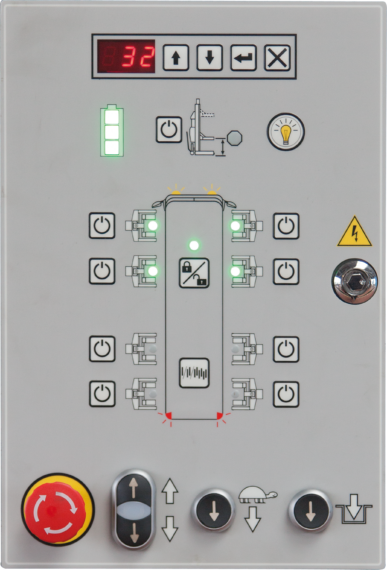

- Intuitive Control

- Faster change of position possible due to forklifts

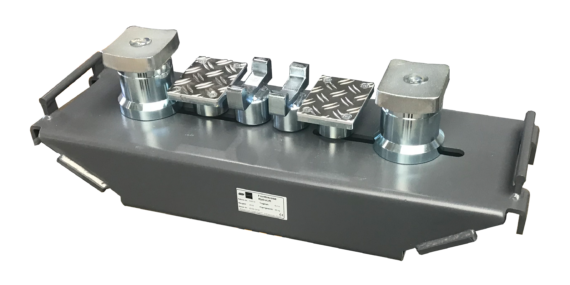

- The VARIO fork ensures the accommodation of different tire sizes without additional adapters: from 570 – 1300 mm – and, of course, Super-Single.

- Generously-sized batteries allow up to 15 lifting and lowering movements with a full load.

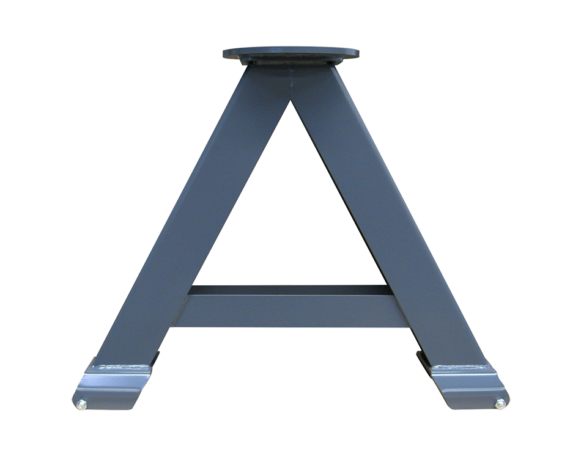

- Movable self-deflecting steering gear with integrated locking brake prevents the unintentional rolling away of the lifting unit.

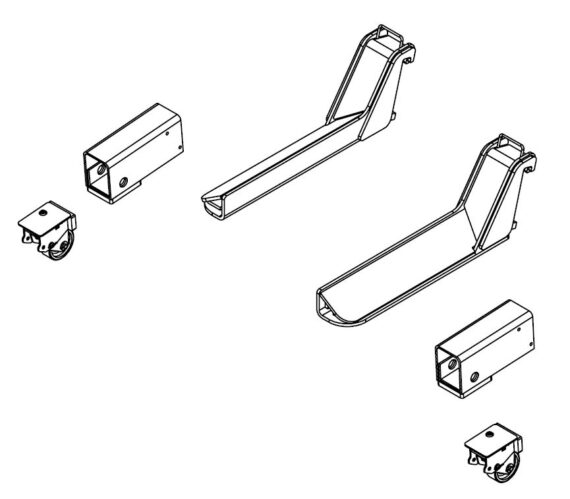

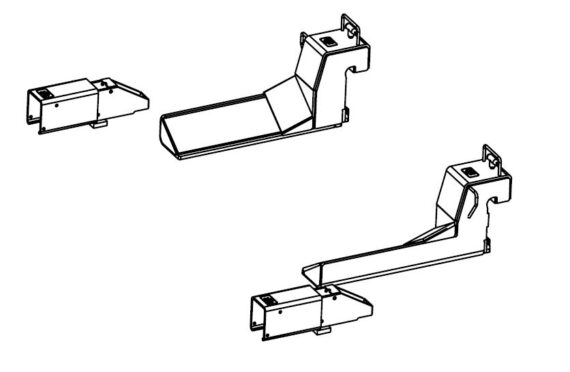

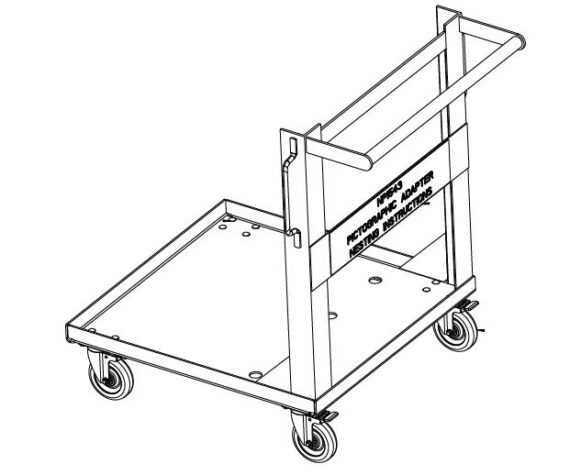

- Forklift adapters allow quick and easy transport of the wheel grippers in the workshop.

- The unique FS profile offers optimum protection of the wheel hub.

- Intuitive control with clearly arranged operating elements.

- Integrated charging device permits charging while operating the HYDROLIFT. One hour of quick-charging allows an additional complete lifting/lowering cycle.

- The modular design allows the additional expansion from 2 to 4, 6 or 8 lifting units.

- Double overload protection due to infinitely adjustable hydraulic safety device (shutoff valve) and self-locking mechanical safety catch.

- Easy-to-understand symbols and clearly arranged push buttons simplify operation. Software updates are carried out via SD card.

- Large-scale production in our ISO-certified production facilities allows consistently high manufacturing quality.

- Wireless communication of the individual lifting units takes place on the basis of IEEE 802.15.4 standards.

- Hydro-Protect: The lifting cylinder is protected against external influences in the lifting carriage. The motor and the hydraulic power units are completely covered.

- Every lifting unit is equipped with an emergency stop button.

- Easy Drive: Low-friction rollers make setting up the workplace literally a breeze.

- Synchronization control guarantees absolute synchronization of all lifting units – even with uneven load distribution.

- No master column – All functions are available on every wheel gripper column.