Description

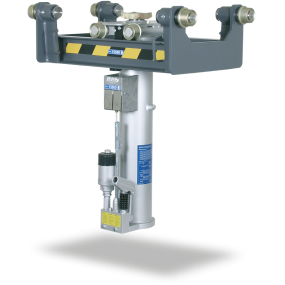

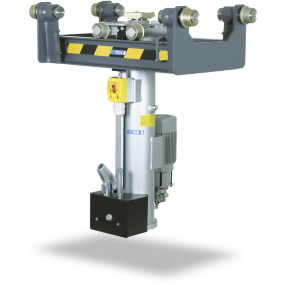

- Ergonomic colour concept We at Blitz are seeing red, at least when it comes to operating our pit jack. All controls are colour-coded red and thus effectively eliminate operator errors.

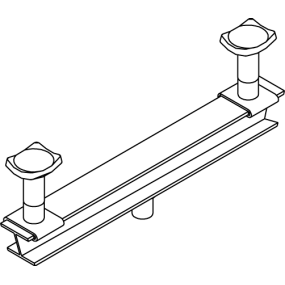

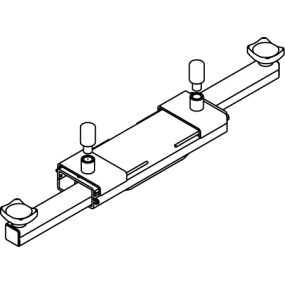

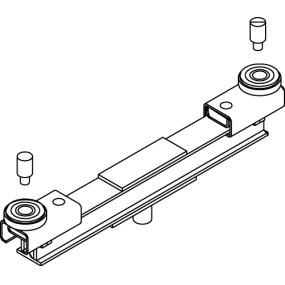

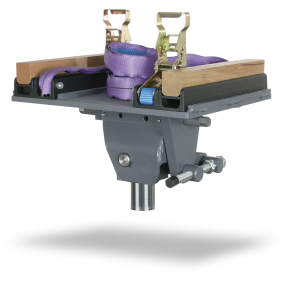

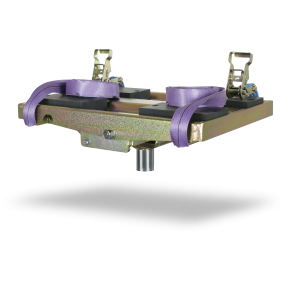

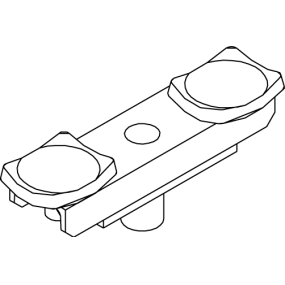

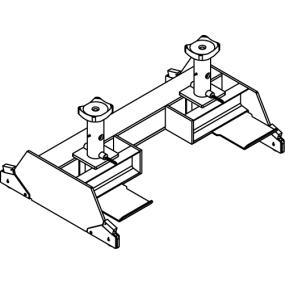

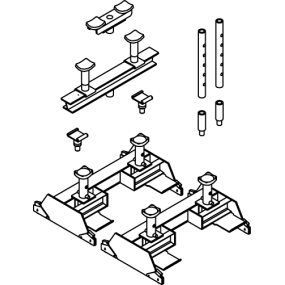

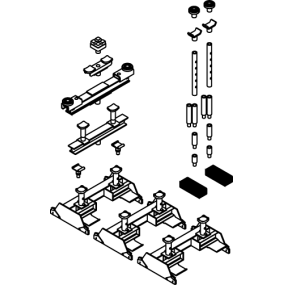

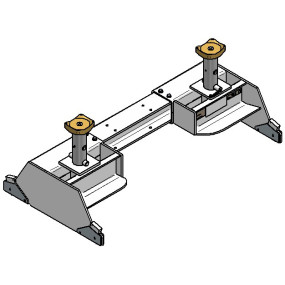

- Ergonomic carriages The new design carriage bring the mechanics closer to the jack and thus closer to the vehicle.

- Integrated toolboxes bring the tool to the mechanic and not vice versa.

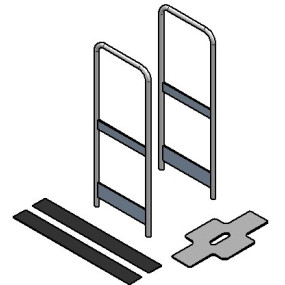

- Sleek design By utilising the lateral adjustability of the lift to the full, the flush to the floor design creates maximum freedom of movement. People can move through quickly at any time – even in exceptional situations.

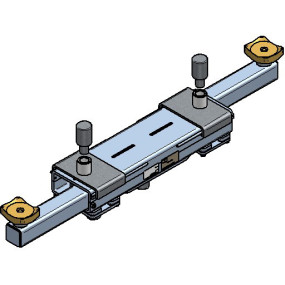

- Hydraulic-pneumatic quick lift Enables the pistons to move rapidly up to the pick-up point.

- Variable pedal-operated precision lift For fine adjustment of the pit jack on the vehicle – important for sensitive lifting as well as when installing engines etc.

- Hydraulic-pneumatic automatic return enables the piston to return quickly with or without load. In contrast to conventional types of pit jacks, the piston is, in effect, “pulled” back to its default position.

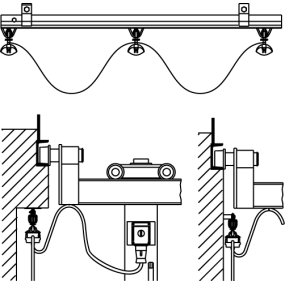

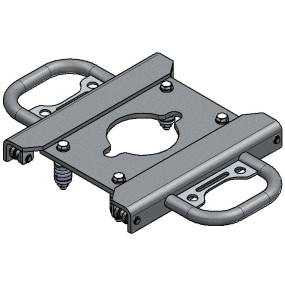

- Operated by foot pedals Floor-running pit jacks from Blitz save power through the use of foot pedals to operate the jacks. Hands also remain free to work on the vehicle.

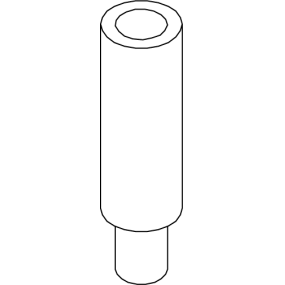

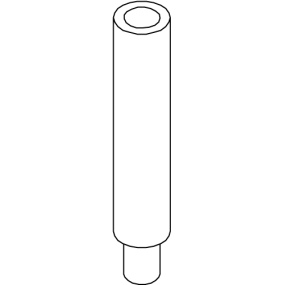

- Rust protection system Fully hydraulic lifting unit – with each lifting and lowering movement, the cylinder is immersed in oil on both sides of the sleeve. The piston as well as the cylinder is thus always completely immersed in oil. This means: no rust on the cylinder wall!

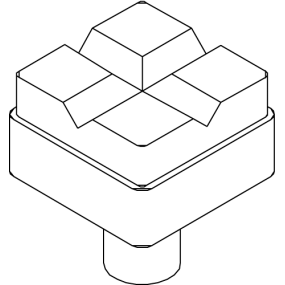

- Carriage rollers fitted with needle bearings The enhanced freedom of movement allows you to slide the jack effortlessly within the pit. All M- and X-carriages are automatically lowered from a load of 0.8t onward.

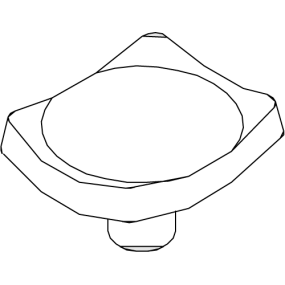

- Extra long cylinder heads The long piston head guarantees optimum absorption of lateral forces. Since loads are picked up in their centre in only very rare instances, this argument takes on extra significance.

- 2-layer surface finish Full surface finish for perfect corrosion protection.