Trailer

Showing 199–297 of 302 results

Mobile column lift ArtisLift MRG-55-4

4 x 5.5 t, electromechanical, cable-bound, lift spindle, mobile, transporter and truck

Mobile column lift ArtisLift MRG-55-6

6 x 5.5 t, electromechanical, cable-bound, lift spindle, mobile, transporter and trucks

Mobile column lift ArtisLift MRG-55-8

8 x 5.5 t, electromechanical, cable-bound, lift spindle, mobile, transporter and trucks

Gearbox lift Junior Jack 1,2 S2

1,2 t, 1100 mm stroke, air-hydraulic

Gearbox lift Junior Jack 2,0 S2

2.0 t, 1100 mm stroke, air-hydraulic

Gearbox lift Master Jack 2,5

2.5 t, 1100 mm stroke, air-hydraulic, foot control

Gearbox lift Master Jack 4,0

4.0 t, 1100 mm stroke, air-hydraulic, foot control

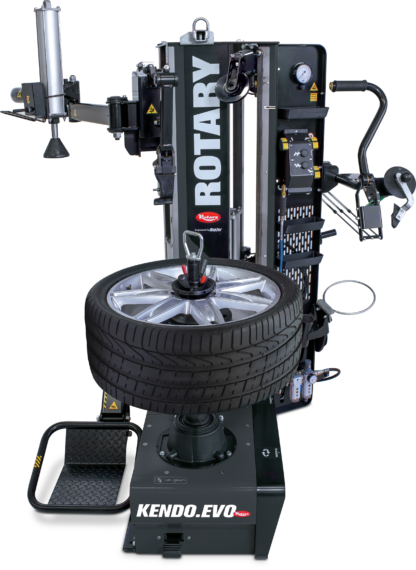

Tyre changer Kendo

Leverless, automatic, passenger car, rim diameter 12 – 30″ | Grey (RAL 7016) | Not available for DACH market

Tyre changer Kendo.Evo-M Pro

Leverless, automatic, incl. pneumatic bead depressor pusher, passenger car, rim diameter 12 – 30″ | Grey (RAL 7016) | wdk certified | Available for DACH market only

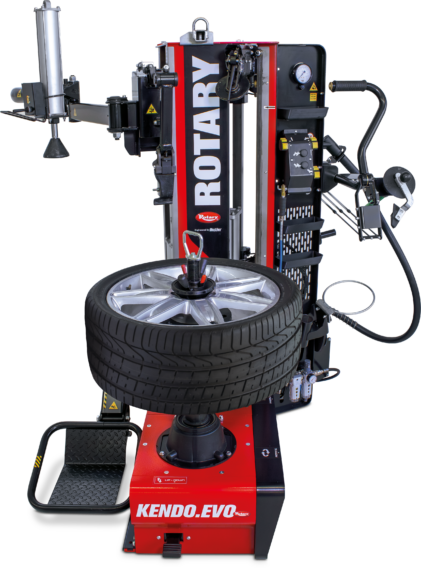

Tyre changer Kendo.Evo-M Premium

Leverless, automatic, incl. pneumatic bead depressor pusher and pneumatic wheel lift, passenger car, rim diameter 12 – 30″ | Grey (RAL 7016) | wdk certified | Available for DACH market only

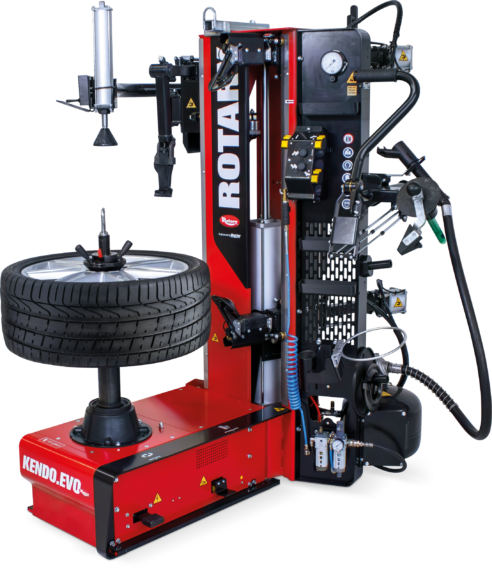

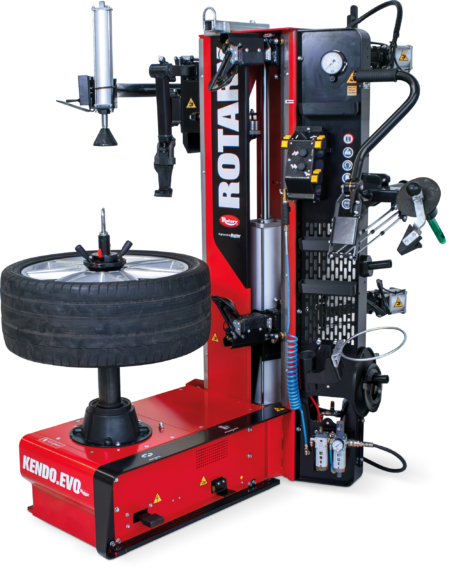

Tyre changer Kendo.EvoFI Premium

Leverless, automatic, incl. tubeless tyre inflation device, pneumatic bead depressor pusher and pneumatic wheel lift, passenger car, rim diameter 12 – 30″ | Red (RAL 3002) | wdk certified | Not available for DACH market

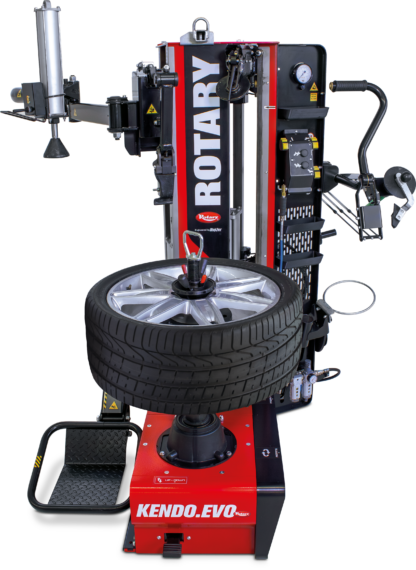

Tyre changer Kendo.Evo Premium

Leverless, automatic, incl. pneumatic bead depressor pusher and pneumatic wheel lift, passenger car, rim diameter 12 – 30″ | Red (RAL 3002) | wdk certified | Not available for DACH market

Tyre changer Kendo.EvoFI Pro

Leverless, automatic, incl. tubeless tyre inflation device and pneumatic bead depressor pusher, passenger car, rim diameter 12 – 30″ | Red (RAL 3002) | wdk certified | Not available for DACH market

Tyre changer Kendo.Evo Pro

Leverless, automatic, incl. pneumatic bead depressor pusher, passenger car, rim diameter 12 – 30″ | Red (RAL 3002) | wdk certified | Not available for DACH market

Tyre changer Kendo

Leverless, automatic, passenger car, rim diameter 12 – 30″ | Red (RAL 3002) | Not available for DACH market

CCD wheel aligner RWA5100HDB.3

2 portable boxes, CCD wheel aligner for trucks, with 6 lowered CCD sensors, 3-point wheel clamps, cylinder adapter kit, 12″ LCD Windows tablet, wheeled suitcase with external power plug and cord

CCD wheel aligner SPEED8080PTWSR.4

8 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWSR.4 (grey)

8 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWS.4

8 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWS.4 (grey)

8 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWSR.4

6 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWSR.4 (grey)

6 CCD truck wheel aligner, with lowered sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWS.4

6 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWS.4 (grey)

6 CCD truck wheel aligner, with standard sensors | incl. 4-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWSR.3

8 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWSR.3 (grey)

8 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWS.3

8 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8080PTWS.3 (grey)

8 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 24″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWSR.3

6 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWS.3

6 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Red (RAL 3002) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner RWA5100HD.3

6 CCD truck wheel aligner, with lowered sensors | incl. 3-point clamps (2 x STDA92), 2 Turntables (STDA29L), open cabinet, 11.6″ LCD Windows tablet, press pedal and steering lock | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner RWA5100HD

6 CCD truck wheel aligner, with lowered sensors | incl. open cabinet, 11.6″ LCD Windows tablet, press pedal and steering lock | 1 x 230 V / 50 – 60 Hz

Air receiver K 1000/11

11 bar, lacquered, horizontal execution

Air receiver K 1000/11

11 bar, galvanised, horizontal execution

Air receiver K 1000/16

16 bar, lacquered, horizontal execution

Air receiver K 1000/16

16 bar, galvanised, horizontal execution

Air receiver K 1500/11

11 bar, galvanised, horizontal execution

Air receiver K 1500/16

16 bar, lacquered, horizontal execution

Air receiver K 250/11

11 bar, lacquered, horizontal execution

Air receiver K 250/11

11 bar, galvanised, horizontal execution

Air receiver K 250/16

16 bar, lacquered, horizontal execution

Air receiver K 250/16

16 bar, galvanised, horizontal execution

Air receiver K 350/11

11 bar, lacquered, horizontal execution

Air receiver K 350/11

11 bar, galvanised, horizontal execution

Air receiver K 350/16

16 bar, lacquered, horizontal execution

Air receiver K 350/16

16 bar, galvanised, horizontal execution

Air receiver K 50/16

16 bar, lacquered, horizontal execution

Air receiver K 50/16

16 bar, galvanised, horizontal execution

Air receiver K 500/11

11 bar, lacquered, horizontal execution

Air receiver K 500/11

11 bar, galvanised, horizontal execution

Air receiver K 500/16

16 bar, lacquered, horizontal execution

Air receiver K 500/16

16 bar, galvanised, horizontal execution

Air receiver K 750/11

11 bar, lacquered, horizontal execution

Air receiver K 750/11

11 bar, galvanised, horizontal execution

Air receiver K 750/16

16 bar, lacquered, horizontal execution

Air receiver K 750/16

16 bar, galvanised, horizontal execution

Air receiver K 90/11

11 bar, lacquered, horizontal execution

Air receiver K 90/11

11 bar, galvanised, horizontal execution

Air receiver K 90/16

16 bar, lacquered, horizontal execution

Air receiver K 90/16

16 bar, galvanised, horizontal execution

Air receiver KS 1000/11

11 bar, galvanised, vertical execution

Air receiver KS 1000/11

11 bar, lackiert

Air receiver KS 1000/16

16 bar, lacquered, vertical execution

Air receiver KS 1000/16

16 bar, galvanised, vertical execution

Air receiver KS 1500/11

11 bar, lacquered, vertical execution

Air receiver KS 1500/11

11 bar, galvanised, vertical execution

Air receiver KS 1500/16

16 bar, lacquered, vertical execution

Air receiver KS 1500/16

16 bar, galvanised, vertical execution

Air receiver KS 2000/11

11 bar, lacquered, vertical execution

Air receiver KS 2000/11

11 bar, galvanised, vertical execution

Air receiver KS 2000/16

16 bar, galvanised, vertical execution

Air receiver KS 250/11

11 bar, lacquered, vertical execution

Air receiver KS 250/11

11 bar, galvanised, vertical execution

Air receiver KS 250/16

16 bar, lacquered, vertical execution

Air receiver KS 250/16

16 bar, galvanised, vertical execution

Air receiver KS 350/11

11 bar, lacquered, vertical execution

Air receiver KS 350/11

11 bar, galvanised, vertical execution

Air receiver KS 350/16

16 bar, lacquered, vertical execution

Air receiver KS 350/16

16 bar, galvanised, vertical execution

Air receiver KS 500/11

11 bar, lacquered, vertical execution

Air receiver KS 500/11

11 bar, galvanised, vertical execution

Air receiver KS 500/16

16 bar, lacquered, vertical execution

Air receiver KS 500/16

16 bar, galvanised, vertical execution

Air receiver KS 750/11

11 bar, lacquered, vertical execution

Air receiver KS 750/11

11 bar, galvanised, vertical execution

Air receiver KS 750/16

16 bar, galvanised, horizontal execution

Air receiver KS 750/16

16 bar, lacquered, horizontal execution

Automatic tyre changer VAS 741065A

Kendo.30 Premium | Leverless, including pneumatic bead depressor pusher and pneumatic wheel lift, passenger car, rim diameter 10 – 30″ | wdk certified

CCD wheel aligner SPEED8060PTWS.3 (grey)

6 CCD truck wheel aligner, with standard sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

CCD wheel aligner SPEED8060PTWSR.3 (grey)

6 CCD truck wheel aligner, with lowered sensors | incl. 3-point wheel clamps, closed cabinet, turntables and 22″ LCD display | Grey (RAL 7040) | 1 x 230 V / 50 – 60 Hz

Mobile column lift HydroLift S3 1-7.5

1 x 7.5 t, electrohydraulic, cable-bound

Portable tyre pressure regulator Pneujet

0-25 bar (0-350 psi), Filling hose with valve screw adapter

Portable tyre pressure regulator Pneujet 1

0-25 bar (0-350 psi), Filling hose with twin hold-on connector

Portable tyre pressure regulator Pneurex

0-4 bar (0-58 psi), Filling hose with single clip-on connector

Portable tyre pressure regulator Pneurex

0-12 bar (0-170 psi), Filling hose with single clip-on connector

Portable tyre pressure regulator Pneurex 1

0-4 bar (0-58 psi), Filling hose with twin hold-on connector

Portable tyre pressure regulator Pneurex 1

0-12 bar (0-170 psi), Filling hose with twin hold-on connector

Portable tyre pressure regulator Pneurex Kombi

0-4 bar (0-58 psi), Filling hose with filling lever/valve adapter for bicycle tyres

Portable tyre pressure regulator Pneurex Kombi

0-12 bar (0-170 psi), Filling hose with filling lever/valve adapter for bicycle tyres