Description

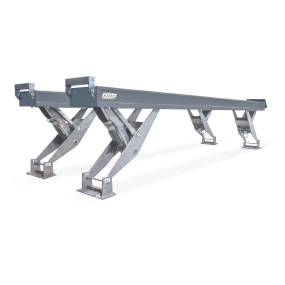

The vertical scissor lifts V55AK54-MB and V45AK48-MB are high-precision lifts for wheel alignment with a lifting capacity of 5.5 t for passenger and utility vehicles and 4.5 t for passenger vehicles.

- Perfect corrosion protection – KTL coating plus powder coating as standard

- Meets requirements of Mercedes-Benz

- A lot of space under the lifting platform with side access

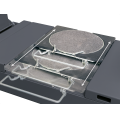

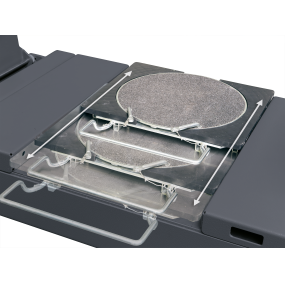

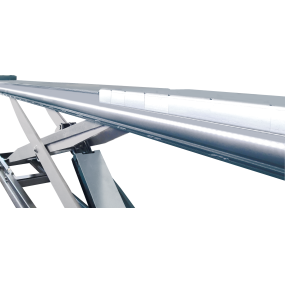

- Integrated recesses with stainless steel supports allow all commercially available rotary disks to be fitted, prevent corrosion and allow the rotary disks to be moved effortlessly.

- The recesses can be closed completely when no rotary disk is used. The filler pieces are provided with plastic stops. Thus, corrosion is prevented and the noise is reduced.

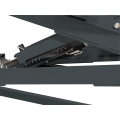

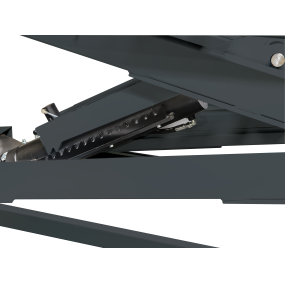

- The main cylinders are equipped with a pneumatically unlockable set-down device. The ratchet strip is screwed and adjustable via screws. This guarantees precise wheel alignment.

- Smartly designed roll-back guards allow the full length of the track to be used.

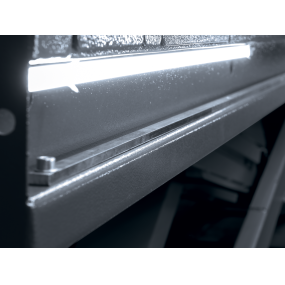

- Galvanized running rail for standard jacking beam (4 t for V55AK54-MB, 2.6 t for V45AK48-MB).

- Reception from Smart to Sprinter van with long wheelbase possible.

- The control panel is equipped with a factory pre-assembled hydraulic unit that can be placed on the left or right.

- Documents or tablet computers will have their place on the control console that is also perfectly suited as a writing support.

- Durable push buttons allow a sensitive operation of the lift.

- The standard CE stop ensures foot protection without a foot guard.

- The lifting scissors engage close to the wheel contact area and thus give the lifting platform high stability. In conjunction with the reinforced driving surfaces that are pre-adjusted at the factory it meets the specifications of Mercedes-Benz.

- The assembly provides maximum clearance under the lifting platform and allows access from the side.

- The flat driving surface allows use at the headlight adjustment area.

- Sturdy plastic balls of the manually lockable sliding plates ensure reliable and smooth operation while rotating brushes prevent the penetration of dirt and ensure a long service life.

- The driving surfaces include the holes for the camera mountings used for the Daimler AG approved Butler wheel aligner ex works.

- Energy kit 220 V and compressed air under the driving surface as standard

- Lighting, MKS bracket as standard