Description

Solutions for the diagnosis and calibration of driver assistance systems

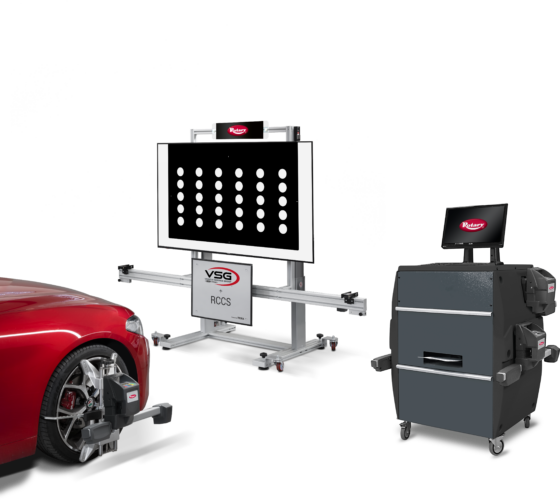

- Extremely practical: ADAS technology integrates with wheel alignment technology to create a single workstation

- Absolute accuracy: the ADAS system makes use of the highest manufacturing technology and state-of-the-art components

- Total safety: the static and dynamic calibration operations processed by the ADAS system guarantee safety for the driver and for those carrying out diagnoses and calibrations

Designed to ensure safety and comfort while driving, the ADAS (Advanced Driver Assistance Systems) are increasingly common in the latest generation of vehicles. Cameras, radar, LIDAR and sensors need to be recalibrated when replaced, also when work needs to be carried out involving them, such as: windscreen and bumper replacement, suspensions repair, wheel alignment, tyre change, engine control unit replacement, etc.

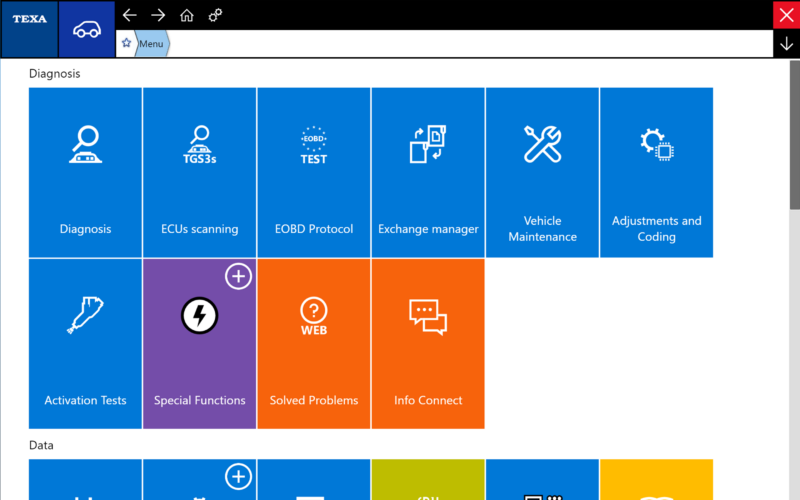

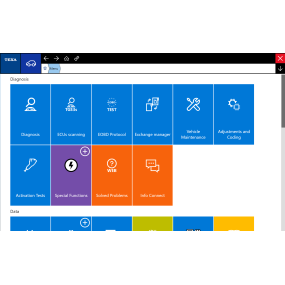

ADAS and wheel alignment – the combination that takes wheel diagnosis efficiency to the highest levels. Thanks to a technological agreement with TEXA, the ADAS calibration system is available on all wheel aligners with PC of the VSG Group. Integration is achieved via an OBD (NANO) communication module with dedicated TEXA software that allows the car to dialogue with the panel directly on the aligner PC.

- Software integration for a complete range of functions. Thanks to software integration, ADAS calibration and wheel alignment functions are run on a single PC. Shared functions allow you to first align the vehicle, secondly to align the ADAS panel, and finally to perform a high quality step by step full ADAS calibration.

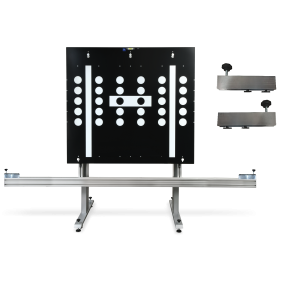

- The ADAS panel is centred using the clamps and the measuring heads of the wheel aligner. The light weight of the measuring heads and the absence of connecting cables between front and rear provide utmost ease of use and accuracy in measuring vehicle angles.

- An upgrade for ADAS integration is possible for models produced from 2020 on. For earlier models, a compatibility check with the VSG Sales team or VSG Aftersales Department is needed.

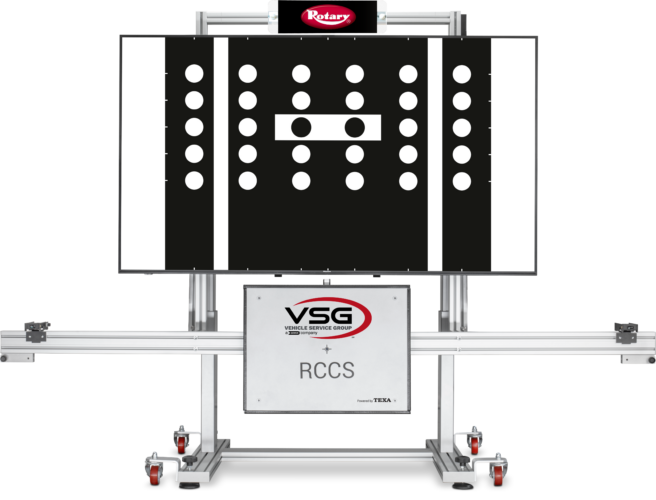

- Digital representation of the panels – The monitor displays the panels required for the calibration using a microprocessor. The microprocessor, installed on the structure, synchronises with the dedicated TEXA software and the panel structure itself.

- Workspace optimisation – The digital nature of the panels frees up considerable workshop space, which would otherwise be occupied by multiple physical panels. The compact structure with the installation of the panel directly on the structure prevents damage and deterioration over time of the panel itself.

- STDARCCS3/MON with monitor dialogues with the TEXA dedicated software and guides the mechanic to the identification of the vehicle and its calibration. The panel is selected and set on the monitor, without any possibility for error. Constant software updates make new vehicles and panels available, as well as help sheets drawn up by brand and model.

- Screen features:

- 4K – High resolution display

- 75″ – Large size, optimal display

- 1:1 – Observes the ratio with precision

- Does not deform or resize

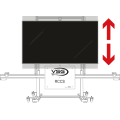

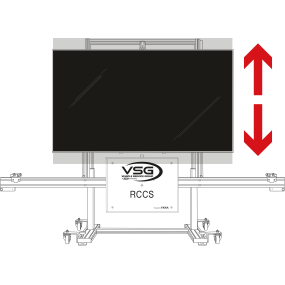

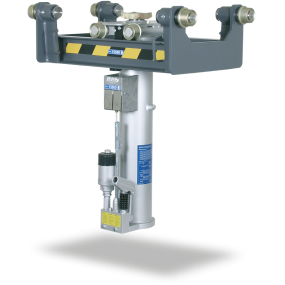

- Height adjustable – Supporting stand, height adjustable thanks to integrated electric drive.

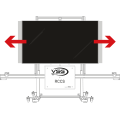

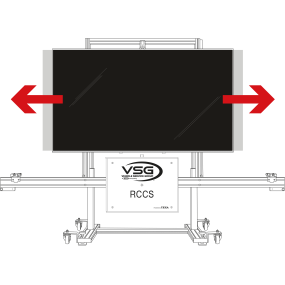

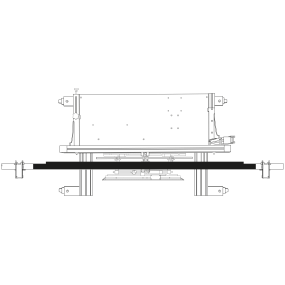

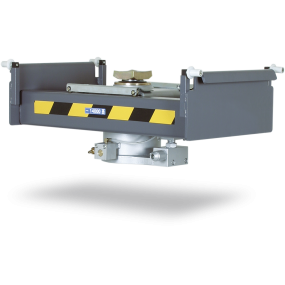

- Lateral translation – Front and lateral easy-tilting frame. Flywheel and laser level allowing even millimetre-perfect lateral moves.

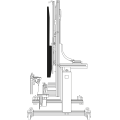

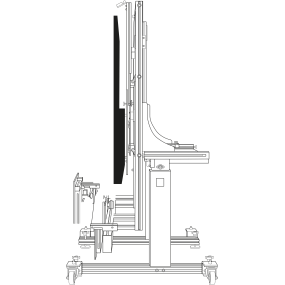

- Front tilting – Laser level, positioned above the structure, that makes identification of the vehicle centre simple, when pointed at the front logo.

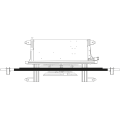

- Side tilting – Horizontal adjustment bar equipped with two spacers and a sliding reflector plate, the latter with a central laser for targeting the front radar.